- UTM MEMBRANE

- Adsorptive Ultrafiltration Mixed Matrix Membrane For Heavy Metals Removal (Aduf Membrane)

- Speek Nf-dmfc Portable Power Generator

- Supported Carbon Membrane For Co2 Capture

- Single-step Fabricated Mt-sofc: Green Energy Converter

- Hybrid Photocatalytic Dual Layer Membranes For Destruction Of Persistent Organic Pollutants

- Nano-Enabled Membrane for CO2 Capture (PI/2016700760)

- Smart Integrated Photocatalyst Adsorbents for Degradation of Emerging Contaminants

- K-Membrane: Smart Membrane for Oily Wastewater Treatment

Clean and safe water supply is identified as one of the most essential basic needs particularly during the occurrence of disasters. The integrated mobile reverse osmosis (RO) water purification system (UTM Membrane) is developed by AMTEC, UTM. Water resources that are used for the treatment of process water is obtained from river water and tube well.

of the most essential basic needs particularly during the occurrence of disasters. The integrated mobile reverse osmosis (RO) water purification system (UTM Membrane) is developed by AMTEC, UTM. Water resources that are used for the treatment of process water is obtained from river water and tube well.

The UTM Membrane is intended to provide quality water support to small units where the distribution of water is not feasible during the occurrence of natural disaster. The system provides clean water support without committing large water production assets from the logistics support structure. The system tailors water production capacity to fulfill the demands of independent Special Operations Forces, detachments and units typically engaged in remote site missions. The research team monitors the quality of water supplied from the RO portable water treatment systems in several phases to ensure the constant supply of clean and safe water to the end users.

Adsorptive Ultrafiltration Mixed Matrix Membrane For Heavy Metals Removal

(Aduf Membrane)

This product called AdUF membrane is a novel adsorptive membrane with unique dual features of simultaneous separation and adsorption which is produced via a simple physical mixing and phase inversion process. It comprised of a very promising additive (hydrous ferric oxide) responsible for improved heavy metals removal (performance) and reduces fouling (loss) that cannot be removed with the common UF membranes. In addition, the incorporation of the nanomaterial resulted to a porous membrane with superior hydrophilicity that improves the flux and adsorptive features of the UF membranes. The ultimate objectives of this product are to provide alternative and feasible method that can treat water laden with heavy metals in single step operation and to ease the fabrication technique with low cost materials.

novel adsorptive membrane with unique dual features of simultaneous separation and adsorption which is produced via a simple physical mixing and phase inversion process. It comprised of a very promising additive (hydrous ferric oxide) responsible for improved heavy metals removal (performance) and reduces fouling (loss) that cannot be removed with the common UF membranes. In addition, the incorporation of the nanomaterial resulted to a porous membrane with superior hydrophilicity that improves the flux and adsorptive features of the UF membranes. The ultimate objectives of this product are to provide alternative and feasible method that can treat water laden with heavy metals in single step operation and to ease the fabrication technique with low cost materials.

- Dual functions adsorptive mixed matrix membrane for simultaneous heavy metal removal and purified water production

- Fabricated via a simple phase inversion process

- Effectively treat various contaminants including heavy metal ions in a single-step procedure

- Robust, stable and sustainable nanocomposite membranes that can deal with wide range of wastewater at minimal cost

Dr. Norhaniza binti Yusof

norhaniza@petroleum.utm.my/ norhaniza@utm.my

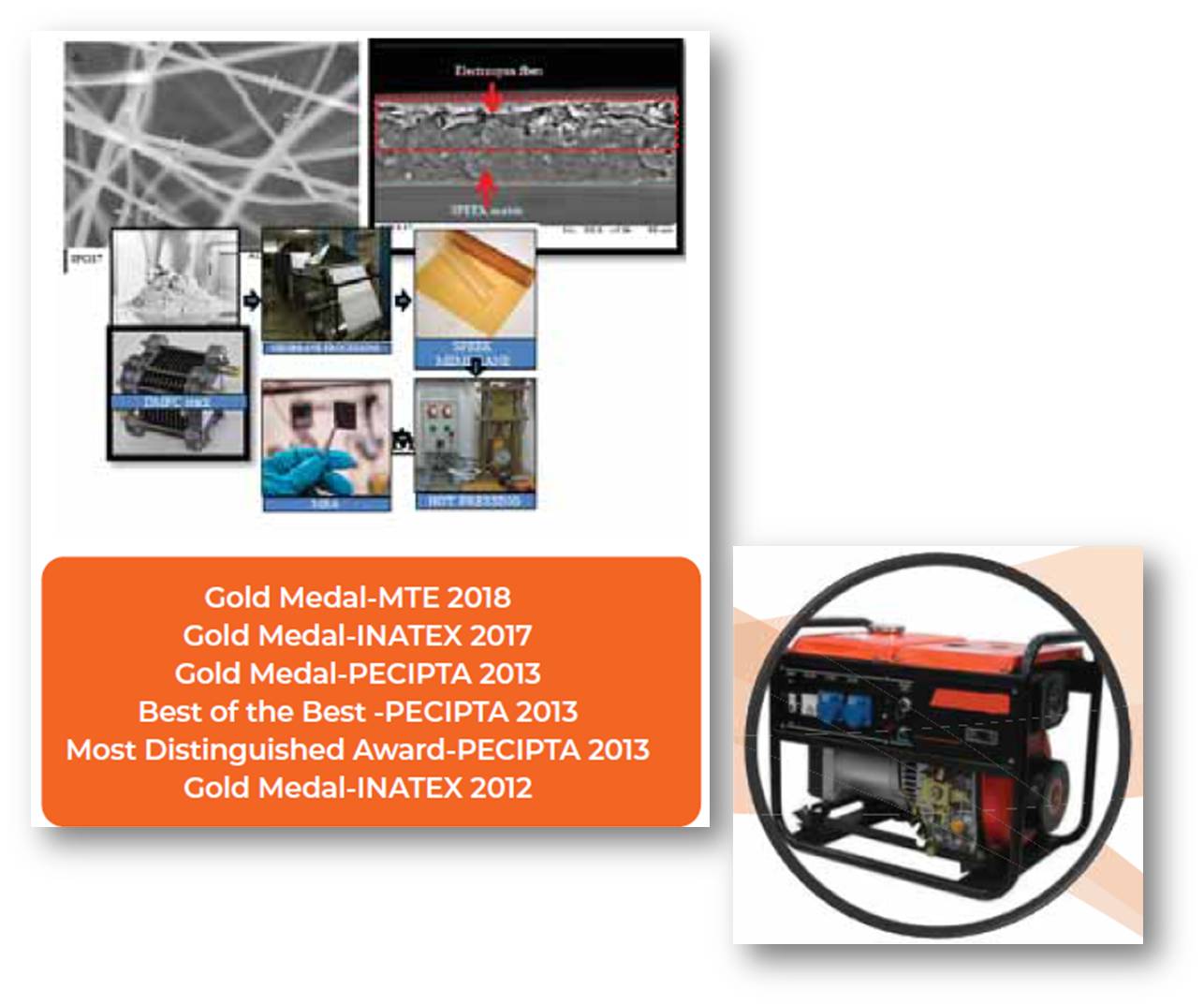

Direct methanol fuel cell (DMFC) portable power generator is a new type of electrical generator which utilised fuel cell technology to develop a clean and green energy. DMFC is an energy conversion device that transform energy from chemical reaction of methanol fuel (cheap price RM1.16/litre and high energy density 3,800 kcal/L) directly to electrical energy using electrochemical principle. At the heart of the fuel cell system, the in-house sulfonated polyethertherketone (SPEEK)-based electrolyte membrane that was produced via novel formulation that consists of clay (Cloisite) in nanofiber form is used instead of commercial Nafion® membrane.

The novelty of this innovation relies on the membrane’s morphological structure in which the fabricated Cloisite clay nanofibers using electrospinning technique were uniformly distributed in the SPEEK polymer matrix. This unique morphology has contributed to an exfoliated dispersion structure of inorganic in organic material that is very desirable structure to obtain high performance for a proton exchange membrane. The SPEEK-Cloisite nanofiber based membrane with 70% cheaper and 80% higher in performance than the commercial Nafion117®. Owing to the significant features of the SPEEK-Cloisite nanofiber electrolyte membrane that has high fuel barrier properties, the SPEEK NF-DMFC power generator exhibited higher energy conversion efficiency, less waste heat, consume less fuel and emit much lesser CO2 gas by-product. Due to its simplicity and small footprint system, SPEEK NF-DMFC power generator is a moving forward technology with high-performance, compact and portable energy generator.

Assoc. Prof. Dr Juhana Jaafar

juhana@petroleum.utm.my

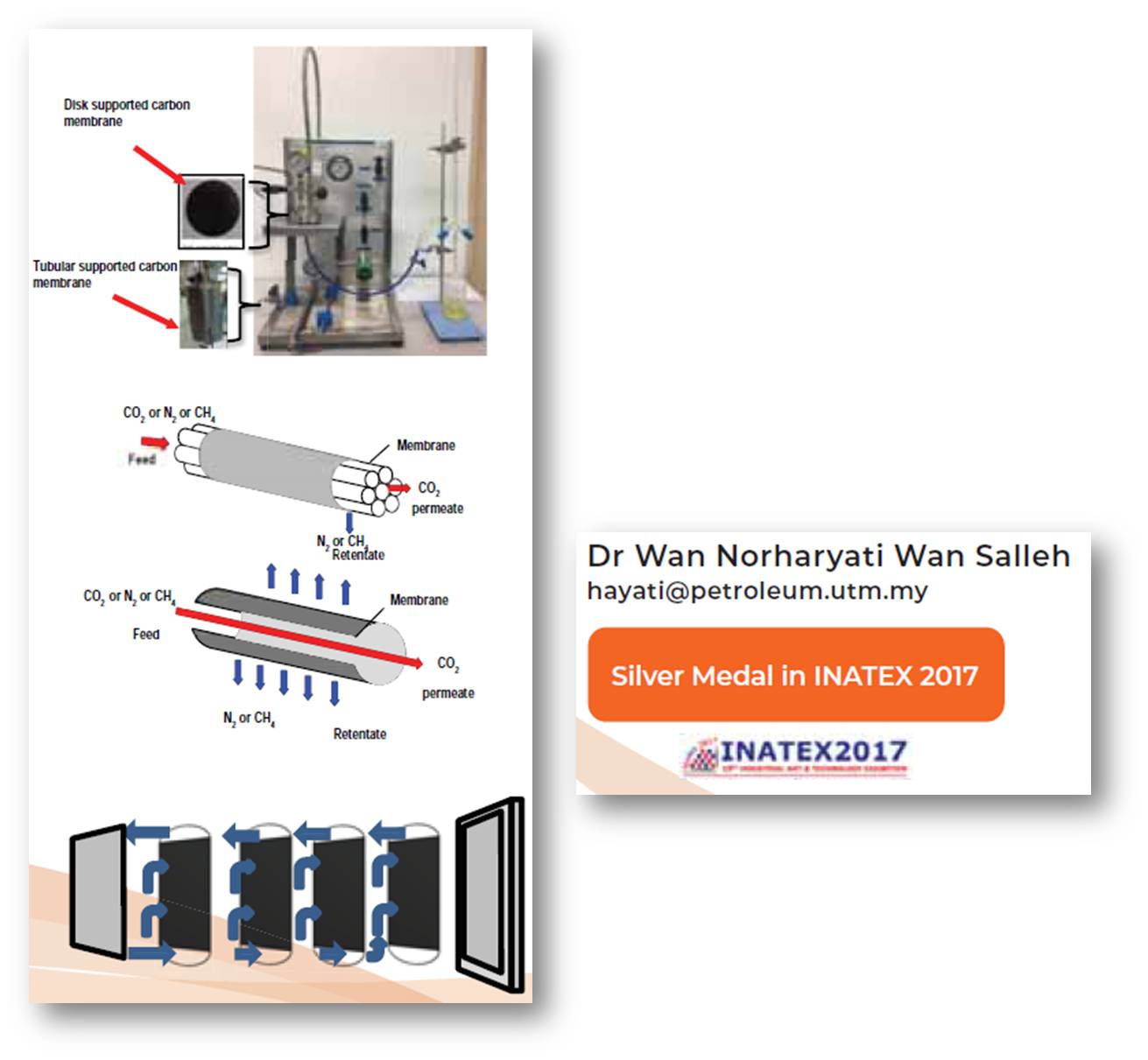

- Supported carbon membrane that

capable to fabricate via a single step coating-carbonization cycle which can reduce production time and cost

capable to fabricate via a single step coating-carbonization cycle which can reduce production time and cost - Can be easily fine tune by controlling the carbonization conditions

- Offer excellent thermal resistance and chemical stability

- Offer longer lifetime compare to unsupported carbon membrane

- Can be fabricated in the form of disk-supported or tubular-supported and up-scaled according to the industry needs

Dr Wan Norharyati Wan Salleh

hayati@petroleum.utm.my

- Small size -> more compact.

- Novel single-step fabrication technique; combine 2 steps into 1.

- Higher volumetric output density (23.2 kWm-2 vs 8k Wm-2 by planar design.

- The global fuel cell market size is estimated to reach $5.20 billion, by 2019 .

- Asia-Pacific is estimated to be the largest revenue-generating region for SOFC .

- It is targeted that at least 350 MW of Malaysia’s energy demand is supplied by alternative energy sources.

- Development of novel electrolyte/anode dual-layer hollow fiber for micro-tubular solid oxide fuel cells (SOFCs) via a promising single-step co-extrusion/co-sintering technique.

Assoc. Professor Dr. Mohd Hafiz Dzarfan bin Othman

hafiz@petroleum.utm.my

Hybrid Photocatalytic Dual Layer Membranes For Destruction Of Persistent Organic Pollutants

M-PORE2ife is a dual layer hollow fiber membranes which fabricated via a single step co-extrusion technique with immobilized titanium dioxide (TiO2) nanoparticles that embedded in their outer layer for hybrid photocatalytic application.

- M-PORE2ife membrane that capable to act for dual function, which is the outer layer for photocatalytic process and the inner layer for separation process.

- M-PORE2ife membrane is an innovative and cost effective solution for destruction of persistent organic pollutants in wastewater.

Simpler fabrication using single step co-extrusion process. No need coating process like other multilayer membrane.

- Consists of two layer with good adhesion

- Thin photocatalytic layer (up to 50μm) onto thick separation layer (about 200μm)

- High loading of photocatalyst (up to 70wt%) for better degradation properties.

- Symmetric structure with long finger-like voids from inner and outer layer

- M-PORE2ife membrane shows superior photocatalytic performance of nonylphenol (one of POPs compound) compared to single layer hollow fibre membranes due to the better dispersion of TiO2 nanoparticles on the outer membrane surface.

Associate Professor Dr. Mohd Hafiz Dzarfan Othman

hafiz@petroleum.utm.my

There has been an increasing research and industry interest in carbon capture through membranes technology, mainly driven by the need for simultaneously reducing greenhouse gas emissions and energy application. This invention involves CO2 capture with a focus on the developments and breakthroughs in membrane material design and separation process engineering. The innovation of this product involves the design of membranes with desirable permeance and selectivity while having chemically and physically stable structures. This goal is achieved through the introduction of the start-of-the-art carbon based nanomaterials into the conventionally used polymer membrane. This membrane is endowed with excellent separation properties and durability for the development of membrane capture processes with optimal configurations to achieve the separation targets (e.g., CO2 removal rate and product purity) at minimum capital and operational expenditures (CAPEX and OPEX). Some of the interesting features of this product are:

industry interest in carbon capture through membranes technology, mainly driven by the need for simultaneously reducing greenhouse gas emissions and energy application. This invention involves CO2 capture with a focus on the developments and breakthroughs in membrane material design and separation process engineering. The innovation of this product involves the design of membranes with desirable permeance and selectivity while having chemically and physically stable structures. This goal is achieved through the introduction of the start-of-the-art carbon based nanomaterials into the conventionally used polymer membrane. This membrane is endowed with excellent separation properties and durability for the development of membrane capture processes with optimal configurations to achieve the separation targets (e.g., CO2 removal rate and product purity) at minimum capital and operational expenditures (CAPEX and OPEX). Some of the interesting features of this product are:

- Carbon nanotubes-enabled membrane with facilitated transport feature

- Tunable nanomaterial properties

- High selectivity and permeability

- Chemically stable

- Low fouling and maintenance

- Cost effective

Dr. Goh Pei Sean

gpsean@petroleum.utm.my/ gpsean@utm.my

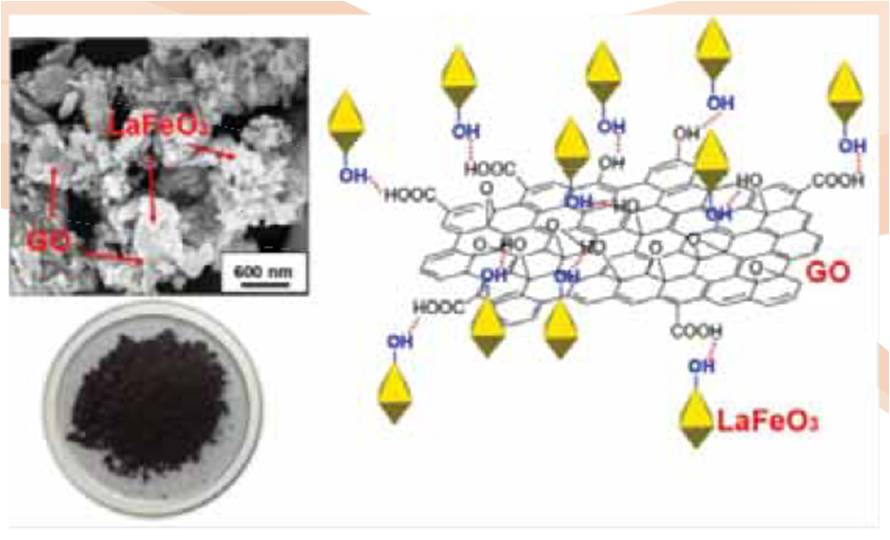

Significant fractions of emergingcontaminants may have adverse effects to human health and harmful to the aquatic environment where they may cause ecological risk such as interferences with endocrine system of higher organisms. The conventional water treatment technologies available nowadays such as adsorption or coagulation do not completely eliminate or destroy the pollutants. The objective of this

Significant fractions of emergingcontaminants may have adverse effects to human health and harmful to the aquatic environment where they may cause ecological risk such as interferences with endocrine system of higher organisms. The conventional water treatment technologies available nowadays such as adsorption or coagulation do not completely eliminate or destroy the pollutants. The objective of this

innovation is to develop an advanced technology for the removal of emerging contaminants namely hybrid integrated photocatalyst adsorbents (ICPA).

Such hybrid system are based on advanced oxidation processes (AOPs) and surface adsorption that will oxidize and mineralize almost any organic molecule, yielding CO2 and inorganic ions as the final products and providing high surface area for reaction. Lanthanum orthoferrite (LaFeO3) is a p-type semiconductor with narrow band gaps of 2.65 eV and one of the most common perovskite type oxides and often applied as photocatalyst slurry for water treatment.

However, the LaFeO3 nanoparticles are easily agglomerated due to high surface energy, which leads to serious decrease of the performance. Immobilization of the photocatalyst on the surface of an appropriate adsorbent is one of the effective ways to overcome the agglomeration problem and increases the pollutants adsorption. Adsorbent supports the photocatalyst as well as concentrates the pollutants around it to increase the contact surface of the photogenerated reactive species. In this work, graphene oxide (GO) as the adsorbents were integrated with a photocatalyst, LaFeO3, designated as integrated photocatalyst adsorbents (IPCA). Graphene oxide, with its unique structure of one-atom thick planar sheets of sp2-bonded carbon atoms closely packed in a honeycomb crystal lattice, has attracted a great deal of scientific attentions because of its outstanding mechanical, electrical, thermal, surface, and optical properties. LaFeO3/GO IPCA was prepared through the synthesis of LaFeO3 using the sol gel method and later GO is added using solution processing. Then, the synthesized LaFeO3/GO IPCA showed an excellent performance in degrading the emerging contaminants.

Awarded Bronze Medal in INATEX 2016

Dr. Farhana Aziz

farhana@utm.my

This product described the innovation of novel low  cost, green ceramic hollow fibre membrane derived from Malaysian kaolin material and prepared via phase inversion and sintering technique for oily wastewater treatment, known as “K -Membrane”. Ceramic suspension was prepared by mixing Malaysian kaolin powder as main material, NMP as solvent, Arlacel P135 as dispersant, PESf as binder and PEG 30000 as pore agent. As a result, robust, cheap, and superior membrane characteristic with estimated cost of only $77/m² which is 549% lower than alumina membrane ($500/m²) and almost similar with commercial polymeric membrane ($50-$70/m²) has been produced. The excellent performance of K-Membrane with 320 L/m² h flux and 99.99% rejection of TOC and turbidity, comparable with commercial polymeric membrane (57.3 L/m² h flux, 99.99% rejection). It should be noted here that K-Membrane possessed outstanding chemical and thermal resistant, thereby, had a lifetime of more than 5 years.

cost, green ceramic hollow fibre membrane derived from Malaysian kaolin material and prepared via phase inversion and sintering technique for oily wastewater treatment, known as “K -Membrane”. Ceramic suspension was prepared by mixing Malaysian kaolin powder as main material, NMP as solvent, Arlacel P135 as dispersant, PESf as binder and PEG 30000 as pore agent. As a result, robust, cheap, and superior membrane characteristic with estimated cost of only $77/m² which is 549% lower than alumina membrane ($500/m²) and almost similar with commercial polymeric membrane ($50-$70/m²) has been produced. The excellent performance of K-Membrane with 320 L/m² h flux and 99.99% rejection of TOC and turbidity, comparable with commercial polymeric membrane (57.3 L/m² h flux, 99.99% rejection). It should be noted here that K-Membrane possessed outstanding chemical and thermal resistant, thereby, had a lifetime of more than 5 years.

- High performance of inexpensive super-hydrophilic kaolin membrane separation for oily-wastewater separation application.

- Enhanced structure prepared via in house phase inversion and sintering system.

Assoc. Professor Dr. Mohd Hafiz Dzarfan bin Othman

hafiz@petroleum.utm.my

capable to fabricate via a single step coating-carbonization cycle which can reduce production time and cost

capable to fabricate via a single step coating-carbonization cycle which can reduce production time and cost